60 Understanding Wood Sizes In Softwood Lumber Coloring Pages

Timbers are used for the structural purpose. That is the lumber must be dried to a customers target moisture content with little variability in the.

Whetstones Staining Wood Japanese Handsaws Make Wood Tools

Wet air expands wood dry air shrinks it.

60 understanding wood sizes in softwood lumber coloring pages. Plain sawn also known as flat sawn is the most cost-efficient method of milling logs into slabs and planks. Denser wood is best for furniture and building while less dense wood can be used in. Examples include fir cedar pine redwood and spruce.

Most softwood lumber is grown in the South or the Pacific Northwest. If the material is delivered at 6 to 8 MC it can experience more than a 2 change in size as it adjusts to the EMC. When short lengths of clear cuttings are required for edge gluing finger-jointing andor laminating production operations Factory Grades provide an economical alternative to other sources of clear lumber.

Find the average yearly change in moisture content. If you are new to buying softwood and hardwood lumber for craft projects or home improvement work one of the first things you notice is that the dimensions by which the wood is sold called the nominal measurements are not the same as the actual measurements. Know that wider boards expand and contract more than narrower ones.

Owing to its longevity and strength maple wood is used in the construction of high-end cabinets flooring furniture and roomskitchen accessories. Miscellaneous - Engineering related topics like Beaufort Wind Scale CE-marking drawing standards and. It is a stage in the process of wood production.

Its the cells and how theyre arranged in bands called rays and the size and distribution of pores that make the difference between fine-textured wood and coarse-textured wood. Finished timber is supplied in standard sizes for the industry. Knotty Alder is chosen for its rustic informal appearance.

Wood as a material but also the standards and practices related to the manufacture of structural wood products such as sawn lumber and glulam. There are however drawbacks to milling in this. Any wood capable of yielding a minimum dimensional size can be termed as a timber or lumber.

The process by which wood and lumber are obtained from trees is known as milling. The technical name for softwood is conifer because many softwood trees bear cones. Pine fir spruce redwood cedar cypress and hemlock.

The strength and weight of wood is its density. 666 clear wood on the worst face. Conifer trees are trees that produce cones and needless.

Knotty Alder Wood Cabinets. There are however drawbacks to milling in this. Lumber is sold in various forms sizes types and cuts.

There are however drawbacks to milling in this. Measure the boards width. This Standard specifies nominal sizes of unplanned square-edged and unedged broadleaved saw timber.

These characteristics are used to describe the different types of wood lumber. 833 clear wood on the worst face. Plain sawn also known as flat sawn is the most cost-efficient method of milling logs into slabs and planks.

However to be successful in this market quality drying is a prerequisite. At least 6 inches wide and 8 to 16 feet long. This means that with time light-hued maple lumber will turn into a dark color due to exposure to oxygen and sunrays.

Alder is a smooth hardwood with color and graining similar to Cherry ranging from a light honey color to a reddish-brown hue. Like oak wood maple wood is also notorious for changing its color over time. Species affects the amount of movement.

Wood expands and contracts mostly across its width. Thats because the primary users of hardwoods red oak cherry maple etc build custom or made-to-fit products like furniture and cabinetry where uniform sizes in the raw material is unnecessary and more troublesome. It is achieved by milling parallel through the log minimizing waste and maximizing lumber and slab size.

Basically timber or Lumber is a wood or firewood of growing trees. Plain sawn also known as flat sawn is the most cost-efficient method of milling logs into slabs and planks. 1 ABNT NBR ISO 89032011 - Broadleaved sawn timber - Nominal sizes Scope.

A piece of 1 x 4 pine for example actually measures 34 inch thick and 3 12 inch wide while a 2 x 4 framing stud is. It is achieved by milling parallel through the log minimizing waste and maximizing lumber and slab size. Softwoods refer to woods that are processed from coniferous trees.

In the broadest terms trees and their respective lumber are classified into two general classes hardwoods and softwoods. Softwood trees are scientifically known as gymnosperms. Texture means the relative size as well as the amount of variation in size of the wood cells.

Softwood vs Hardwood Wood is typically classified as being either a softwood or a hardwood. Minimum 3 inches wide and 4 - 16 feet long. While you might be used to seeing sizes like 16 or 28 in lumberyards for softwoods fir pine cedar etc the hardwood industry takes a different approach.

Knots vary in size and distribution and include tight sound knots as well as rustic open and split knots. It is achieved by milling parallel through the log minimizing waste and maximizing lumber and slab size. Certain projects may require one or more of these specific traits.

Softwood trees are evergreen or needle-bearing eg. Factory and Shop Grade lumber products are intended specifically for remanufacture into such items as doors windows furniture frames mouldings boxes and cabinetry. Those woods which are adapted for building purposes are timbers.

Use a moisture meter to note the highest moisture content MC. Measure Width in inches. There is a great opportunity for softwood mills to enter into the value added markets arena including lumber used for moulding doors windows and furniture.

In most of North America exterior humidity levels range from 60 RH to 70 RH in summer and winter but are lower in the Southwest and higher near large bodies of water.

Journal Of The Korean Wood Science And Technology

Journal Of The Korean Wood Science And Technology

Journal Of The Korean Wood Science And Technology

Journal Of The Korean Wood Science And Technology

Journal Of The Korean Wood Science And Technology

Read Wood Composites Online By Elsevier Science Books

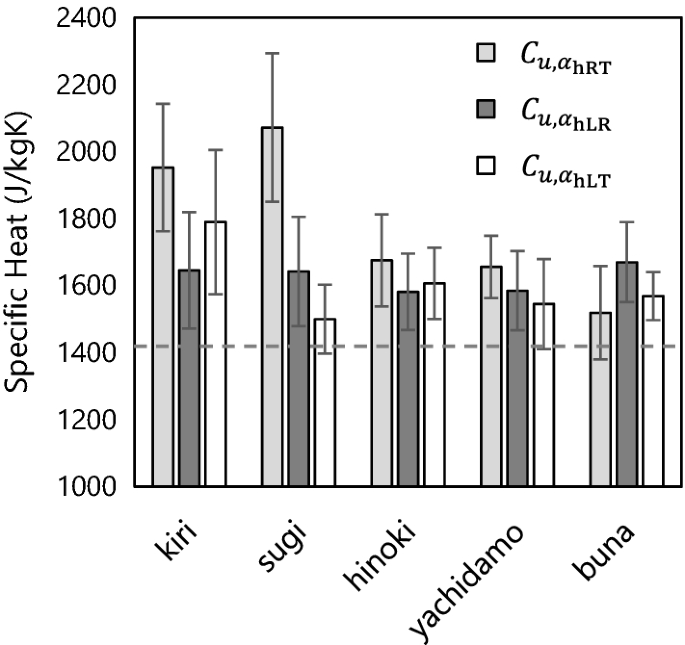

Thermal Properties Of Wood Measured By The Hot Disk Method Comparison With Thermal Properties Measured By The Steady State Method Journal Of Wood Science Full Text

Wood Products Production And Trade Statistics Explained

How The Janka Hardness Scale Can Help You Choose Your Flooring Aco Hardwood Types Flooring Hardwood

Turning Spa Ted Wood Wood Tools

Epic Lumber Dimensions Guide And Charts Softwood Hardwood Plywood Home Stratosphere

Epic Lumber Dimensions Guide And Charts Softwood Hardwood Plywood Home Stratosphere

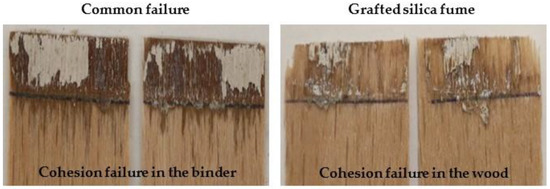

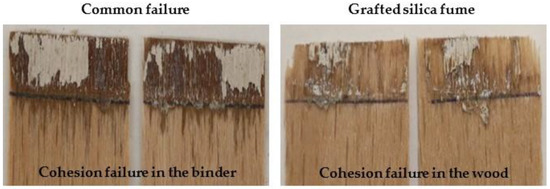

Pdf 9 Wood Adhesion And Adhesives

Journal Of The Korean Wood Science And Technology

Applied Sciences Free Full Text Geopolymer Bonded Laminated Veneer Lumber As Environmentally Friendly And Formaldehyde Free Product Effect Of Various Additives On Geopolymer Binder Features Html

Read Wood Frame House Construction Online By Gerald E Sherwood And Robert C Stroh Books

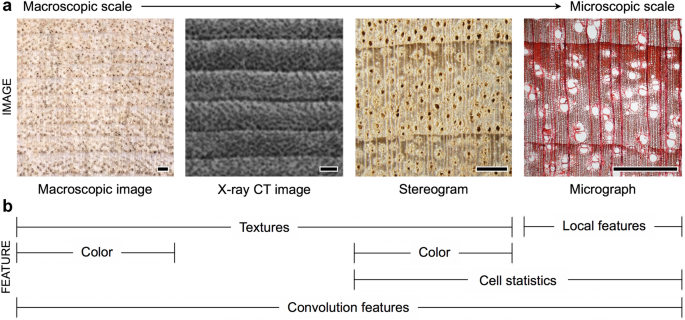

Computer Vision Based Wood Identification And Its Expansion And Contribution Potentials In Wood Science A Review Springerlink